As a technology proposal company, this Laboratory makes its presence known in response to the words "Is this possible?" from our customers.

Please feel free to consult us on your technology challenges.

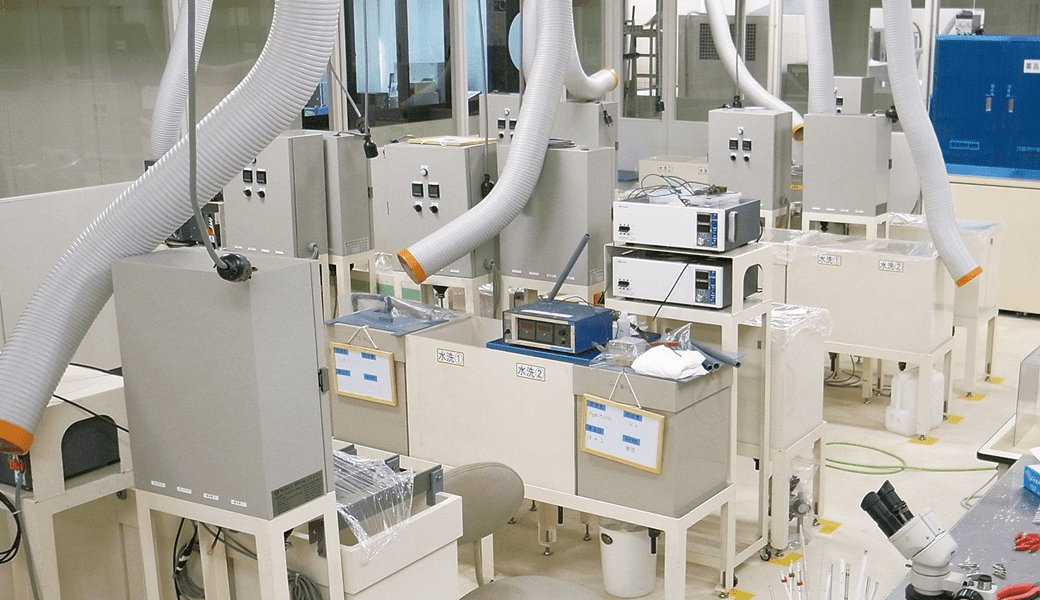

Research laboratory

As a foundation for the new Surface Treatment Laboratory, beakerwork is mainly conducted in this laboratory.

Prototype room

Possibilities exploited from research with scaled-up facilities are guided to stable production in this prototype room.

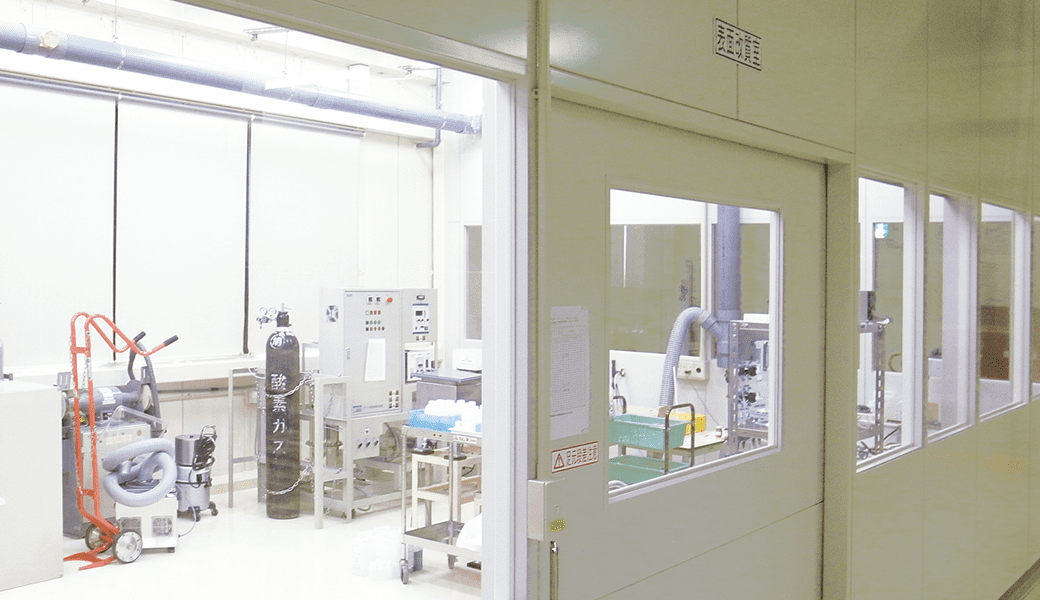

Surface modification room

Not only plating but also new films as well as new methods and other new-generation surface treatments are researched in this surface modification room.

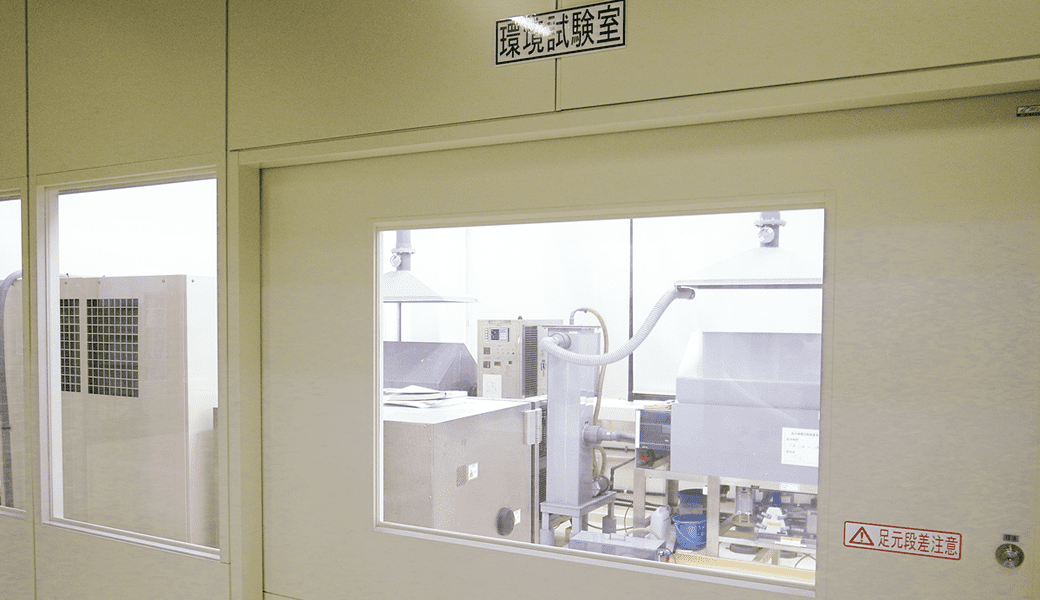

Environmental test room

Environmental performance evaluation is a critical element in making technology needed by society.

Technologies for plating films not containing environmental toxins and eco-friendly plating processes have been developed.

This plating technology having been originally developed as "lead-free" solder plating is highly environment-responsive. It excels in solderability and whisker suppression, and has a solid record of mass production.

Features:

- Ability to suppress whiskers

- Suppression of heat discoloration after installation

- Good solderability

- Processability to center carrier items

This plating technology, which can be said to be the ultimate measure against whiskers, has been developed with the certification of "supporting industry" by the Ministry of Economy, Trade and Industry. This can be applied to all sorts of plating methods.

Features:

- High ability to suppress whiskers

- Good solderability

- Low insertion force (50% reduction in comparison to tin reflow plating)

Our eco-friendly trivalent chromium conversion treatment having been introduced ahead of other companies has a solid record of more than 15 years. This can be applied to unichrome, colored, black, and various other appearances.

Features:

- High environmental responsiveness

- Excellent bactericidal property and corrosion resistance

- Solid working record

- Applicability to a wide variety of appearances

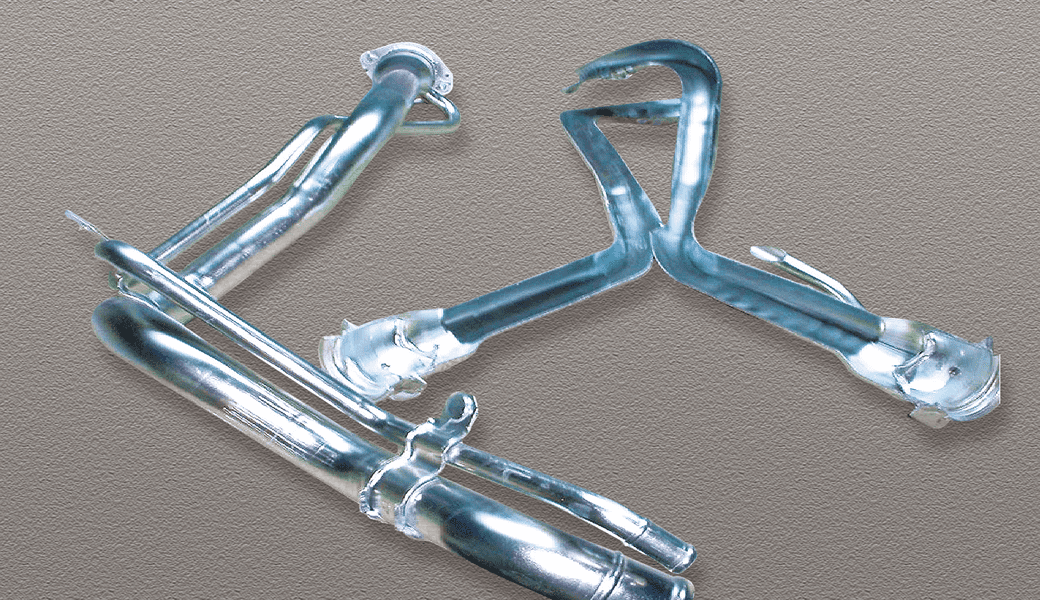

Technologies to plate materials that are said to be unplatable or poorly platable have been developed.

Being certified as a new partnership by the Ministry of Economy, Trade and Industry, we have succeeded in developing a technology to add a highly corrosive-resistant film to magnesium-based materials, which are lightweight and suitable for recycling, so as to compensate for their shortcomings.

Features:

- High corrosion resistance

- Eco-friendly process

- All sorts of plating possibilities

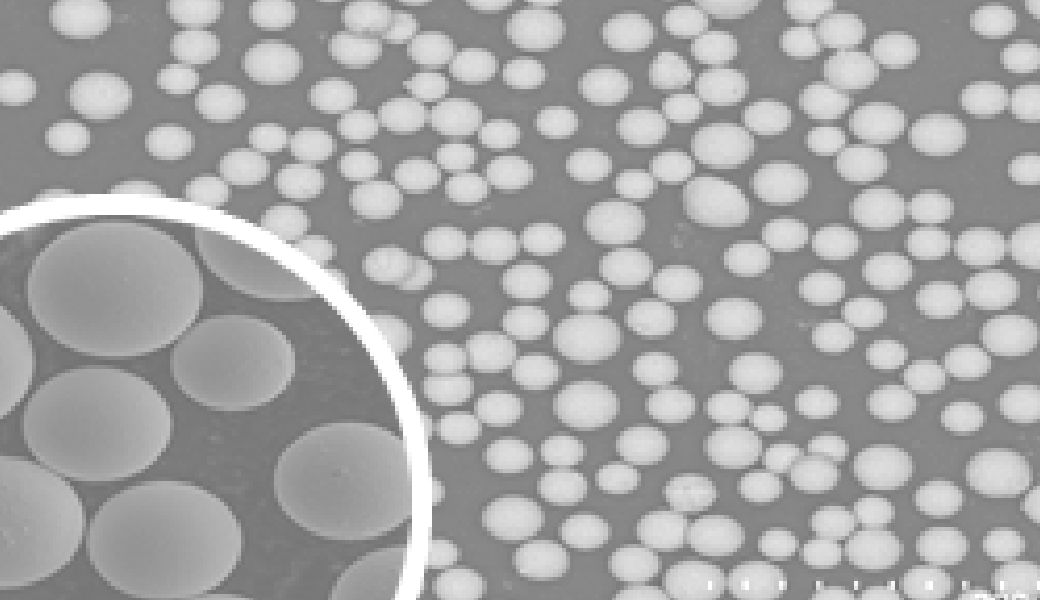

This technology to plate each one of nano- and micro-sized carbon, resin, and metallic fine particles contributes to development of new functional materials, etc.

Features:

- Applicability to carbon, resin, and various other materials

- Applicability to nano-sized particles

- All sorts of plating possibilities

High plating adhesion properties can be secured even under a thermal-resistant environment of 900°C by this special technique having been developed with the certification of "supporting industry" by the Ministry of Economy, Trade and Industry.

Features:

- High adhesion properties

- High thermal resistance

- All sorts of plating possibilities

Technologies for plating films having unprecedented surface characteristics have been developed.

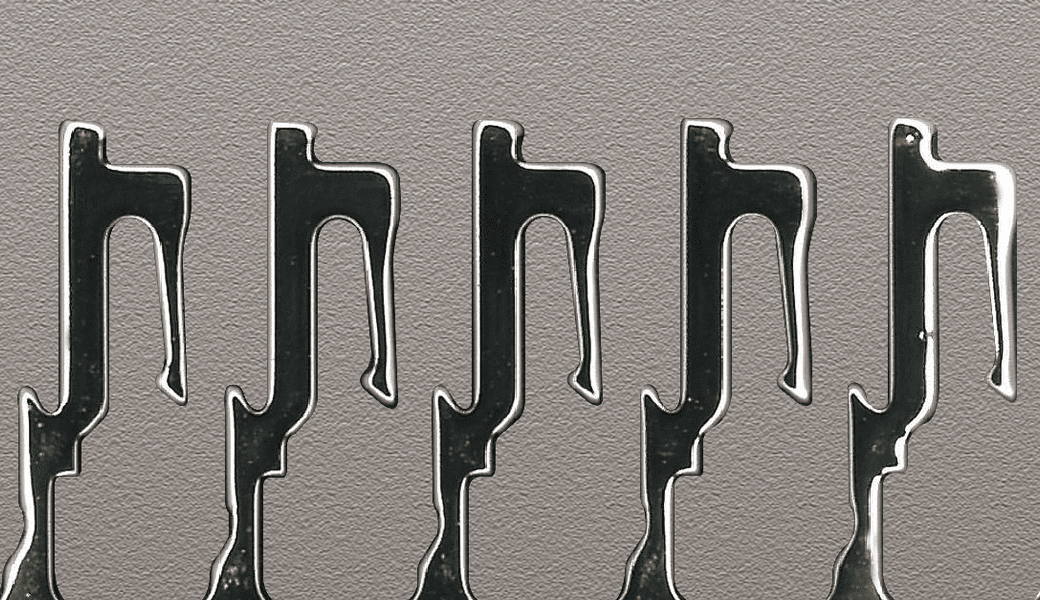

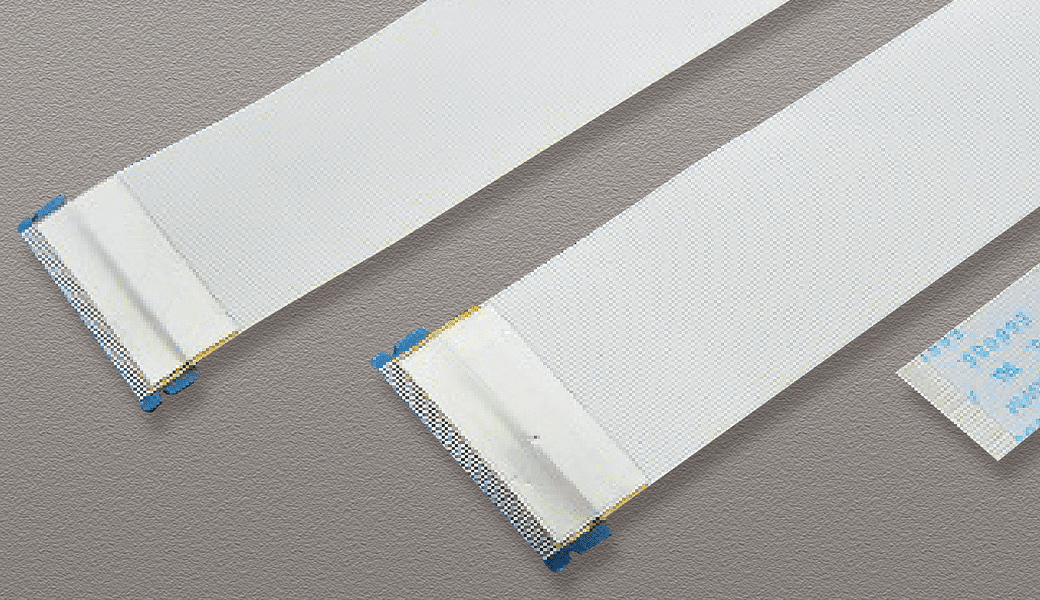

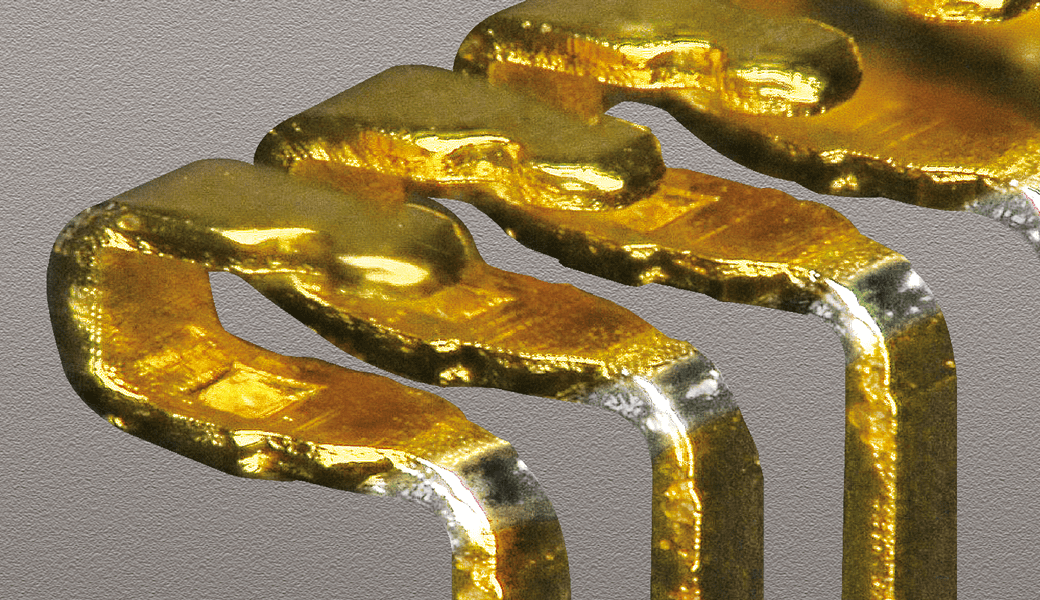

This original silver plating comes with "hardness" and "flexibility" like green bamboo. Production is possible in batch type and hoop type.

Features:

- High bending adhesion properties

- High hardness (low aging degradation)

- High productivity (hoop plating)

- Partial plating possible

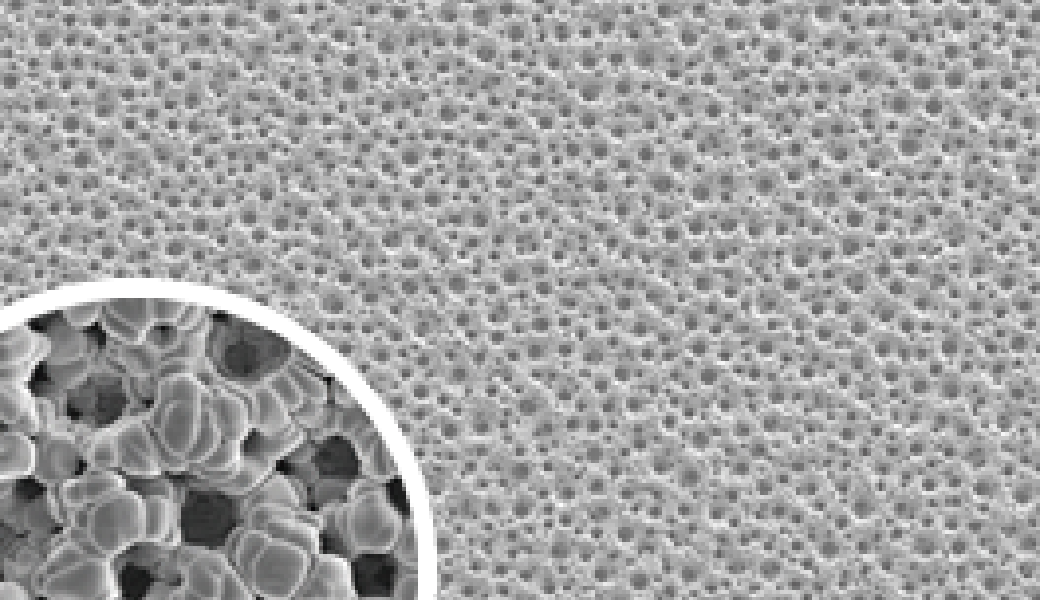

Porous surface conformation increasing the surface area is realized by controlling "precipitation." Surface roughness and specific surface area are considerably improved by this nickel plating.

Features:

- Improved surface roughness

- Increased specific surface area

- High surface smoothness

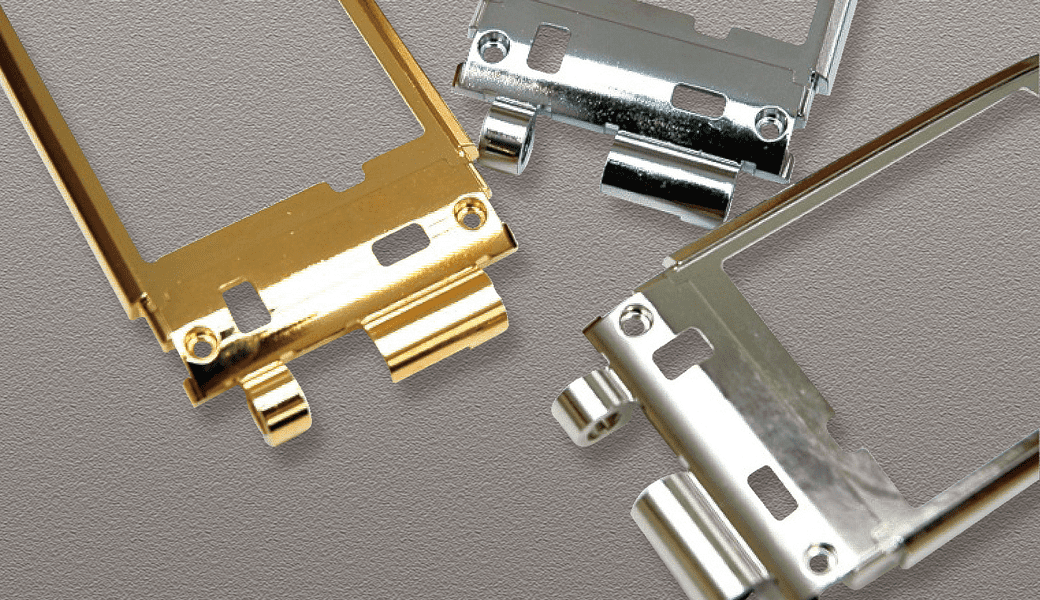

Technologies that can lead to resource saving in expensive noble metal plating, such as gold and silver, as well as cost saving have been developed.

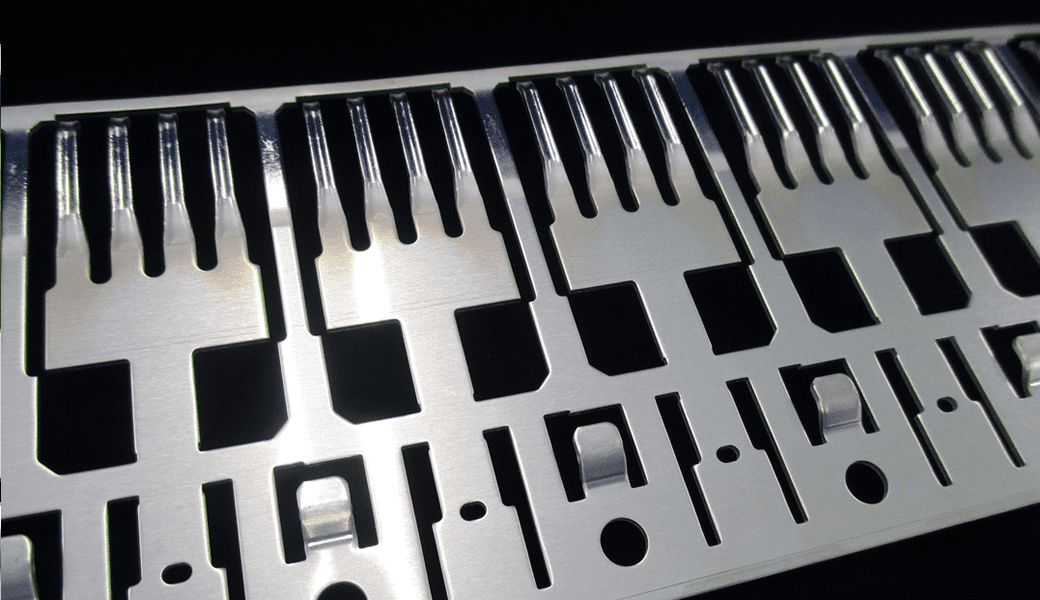

By this technology, only necessary sections are plated with noble metals. This technology contributes to reducing manufacturing costs and also saving resources by omitting noble metals from unnecessary sections.

Features:

- Plating for only necessary sections possible

- High area accuracy (dimension error 0.25mm or less)

- Saving of noble metal resources (1/10 in our comparison)

- Applicability to molded items

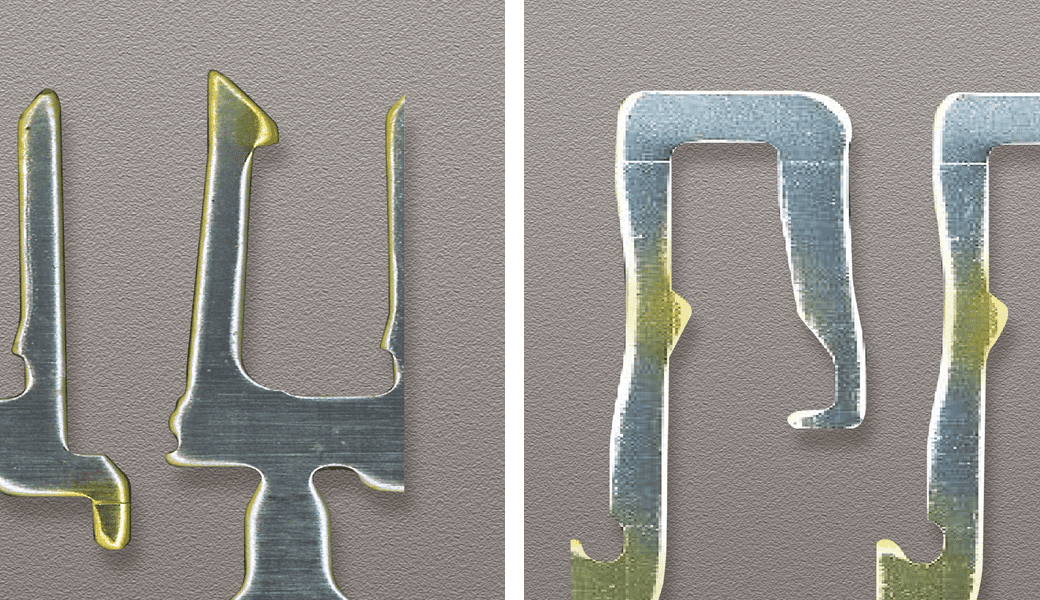

This gold and nickel plating technology with high area accuracy in a stripe state enables nickel barrier formation even in complex shapes.

Features:

- Stripe plating

- High area accuracy (Ni width 0.5±0.2mm)

- Plating for end faces possible

- Applicability to molded items

| 1998 - 2003 |

Started original development of tin reflow plating and established the technology as an alternative to solder plating. |

|---|---|

| 2000 - 2001 |

Received subsidy from Japan Small Business Corporation with "basic research on lead-free solder plating." |

| 2002 |

Received subsidy from Okayama Prefecture and Okayama City with "precision parts gold plating." |

| 2003 - 2006 |

Established precision parts gold plating technology. |

| 2003 - 2005 |

Received consignment grant from Chugoku Bureau of Economy, Trade and Industry for "plating on magnesium (1)" as a "consortium R&D project for regional revitalization." |

| 2004 |

"Whisker-free lead-free solder plating" certified as "Okayama Wagasha no Waza (our company's technique)" by Okayama Prefecture. |

| 2005 - 2008 |

Received subsidy from Chugoku Bureau of Economy, Trade and Industry for "plating on magnesium (2)" as a cross-field-partnership new business development plan (new partnership). |

| 2005 |

Received excellence award at the "1st Monodzukuri Nippon Grand Award" for "development and practical use of innovative manufacturing technology for magnesium alloy bodies for IT devices." |

| 2006 - 2010 |

Received consignment grant from Chugoku Bureau of Economy, Trade and Industry in the Strategic Core Technology Advancement Program (hereinafter, "Supporting Industry Program") for "development of monocrystal tin plating (environmentally-friendly lead-free plating)." |

| 2009 |

Received "Okayama industry-academia-government collaboration grand prize" for "development and practical use of innovative manufacturing technology for magnesium alloy bodies for IT devices." |

| 2009 - 2010 |

Received consignment grant from Chugoku Bureau of Economy, Trade and Industry in the Supporting Industry Program for "plating on graphite." |

| 2013 |

Launched "OM Sangyo Co., Ltd. Surface Treatment Laboratory" on the 7th floor of the first factory. |

| 2013 - 2014 |

Received subsidy from the Ministry of Economy, Trade and Industry in a program to support prototype development by manufacturing SMEs and micro-enterprises in FY2012 (manufacturing subsidy) with "formation of highly functional thin films by cold-spraying on aluminum." |

| 2014 - 2015 |

Received Tochigi Future Challenge subsidy from Tochigi Prefecture for "hard silver plating on large-current connector terminals." |

| 2015 - 2018 |

Received consignment grant from Chugoku Bureau of Economy, Trade and Industry in the Supporting Industry Program for "plating on glass substrate." |

| 2018 - 2019 |

Received FY2017 manufacturing subsidy from Okayama Prefecture for "high-speed copper plating." Received FY2018 next-generation industrial research & development subsidy from Okayama Prefecture for "anodic aluminum oxide interposer." |