Two parts moving in contact always generate friction. Plating with lubricity is intended to decrease the friction between the rubbing surfaces and prevent wear or seizing-up of materials. Generally, soft plating films are suitable because conformability and a low friction coefficient are key points for improvement of lubricity. Recently, such composite plating as highly lubricious particles, like Teflon or molybdenum disulfide, dispersed and co-deposited in hard nickel-phosphorous plating film surface plays an active part under wear environments in which lubricating oil cannot be used.

| Type of plating | Characteristic value | Uses |

|---|---|---|

| Soft plating | - Silver plating, indium plating, tin plating, tin-lead alloy plating, lead-indium alloy plating - Conformability and lubricity are excellent. - Hardness of tin plating film Hv 3~60 - Lead and indium are softer than tin. Sn < Pb < In |

Pistons and piston rings of internal combustion engines, bearings, screws of molding machines, etc. |

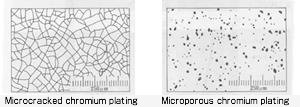

| Hard plating | - Microporous chromium plating + oil retention - TEFLOK (product name) with solid lubricant Teflon impregnated in microporous chromium plating film - Electroless nickel-Teflon composite plating, electroless nickel-molybdenum disulfide composite plating, electroless nickel-graphite fluoride composite plating, electroless nickel-phosphorus-boron nitride composite plating |

Appearance photo of chromium plated surfaces

increasing the oil retaining ability

(From “Kuromu Mekki”; Matsuhei Kishi,

Nikkan Kogyo Shimbun Ltd.)