Releasability of plating is an indispensable function to facilitate removal of products from various molds, while composite functions, including wear resistance, lubricity, thermal resistance & corrosion resistance, need to be combined to prolong the life of molds.

| Type of plating | Characteristic value | Uses |

|---|---|---|

| Industrial chromium plating | - The life of molds is dramatically prolonged by good releasability as well as wear resistance and high hardness. | Various molds |

| - Chromium-PTFE (Teflon) composite films with chromium-plating-specific microcracks or micropores impregnated with PTFE, which excels in self-lubricity and non-adhesiveness has been commercialized. | ||

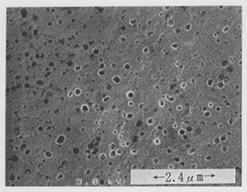

| Releasable composite plating | - Combining the excellent non-adhesiveness, low friction coefficient, and self-lubricity of graphite fluoride particles or Teflon particles with the excellent uniform electrodeposition properties of electroless nickel plating, electroless nickel-graphite fluoride composite plating and electroless nickel-Teflon composite plating have been commercialized. | Plastic lenses, molds |

SEM photo of nickel

—phosphorous-Teflon composite plating