By plating while fine particles 100nm to several micrometers in particle size are suspended in an electro/electroless plating solution, a composite plating film containing these fine particles can be obtained. Since matrix plated metals and fine particles dispersed can be selected according to functions required, it is advantageous for making plating films highly functional. When the dispersed particle size is nano-level, the performance is dramatically improved.

| Type of plating | Features (characteristic value) |

|---|---|

| Matrix plated metal | Nickel, nickel-phosphorus, tin, copper, silver, gold, iron, zinc, chromium, cobalt, and their respective alloys |

| Fine particles dispersed | - Wear resistance: Silicon carbide (SiC), alumina (Al2O3), carbon nanotube, chromium carbide (Cr2O3), diamond - Lubricity: Teflon -(CF2-CF2)n-, graphite fluoride -(CF)n-, graphite (C), molybdenum disulfide (MoS2), boron nitride (BN) - Bondability: Epoxy resin, silica (SiO2) - Fluorescence: Fluorescing dye, fluorescent pigment - Bactericidal property: Titanium oxide (TiO2) - Non-adhesiveness: Teflon -(CF2-CF2)n- |

| Electro/electroless nanoparticle-dispersed composite plating | Nickel-Teflon composite plating (mold releasability, lubricity), nickel-diamond composite plating (wear resistance), nickel-graphite composite plating (lubricity), nickel-molybdenum disulfide composite plating (lubricity), nickel-catalytic particle composite plating (electrode catalyst), nickel-zirconia gradient plating (thermal resistance), cobalt-chromium carbide composite plating (thermal resistance and wear resistance), nickel- titanium oxide composite plating (bactericidal property & washability), nickel-Teflon composite plating (non-adhesiveness & washability), zinc-nickel-silica composite plating (corrosion resistance & bondability), tin-silver nanoparticle composite plating (solderability) |

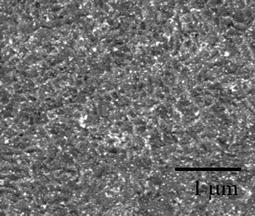

Zn-11wt%Ni-2.1wt%

SEM photo of silica composite plated surface