There are hard plating and soft plating. Also, even on the same plating, the hardness can be changed by changing the plating conditions and heat treatment conditions. For improvement of wear resistance, hard films are generally effective.

| Type of plating | Characteristic value | Uses |

|---|---|---|

| Hard plating | - Hard chromium plating Hv800 - 900 - Nickel - (8 – 10%) phosphorus plating Hv450 – 550 Hv800 – 1000 (heat-treated at 400°C) - Electro nickel plating Dull Hv100 – 250 Bright Hv300 – 350 - Nickel-cobalt alloy plating Hv300 – 600 - Ni-P-SiC composite plating - Rhodium plating, ruthenium plating |

Cylinders, rolls, various molds, gauges, bearings, hydraulic pumps, robots parts, thread feeder roll guides, etc. |

| Soft plating | - Tin-based Hv3 - 60 - Indium-based; softer than tin - Copper plating Hv40 - 85 - Silver plating Hv55 - 90 - Gold plating Hv20 - 80 |

Bearings, piston rings, shafts, etc. |

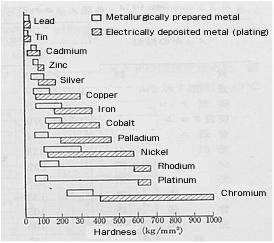

Hardness comparison between plating films

and metallurgically prepared metals

(From “Kuromu Mekki”; Matsuhei Kishi,

Nikkan Kogyo Shimbun Ltd.)